| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : DLX

Model Number : Ni30Cr20

Place of Origin : China Jiangsu

MOQ : 5

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 500 tons per month

Delivery Time : 7-20 days

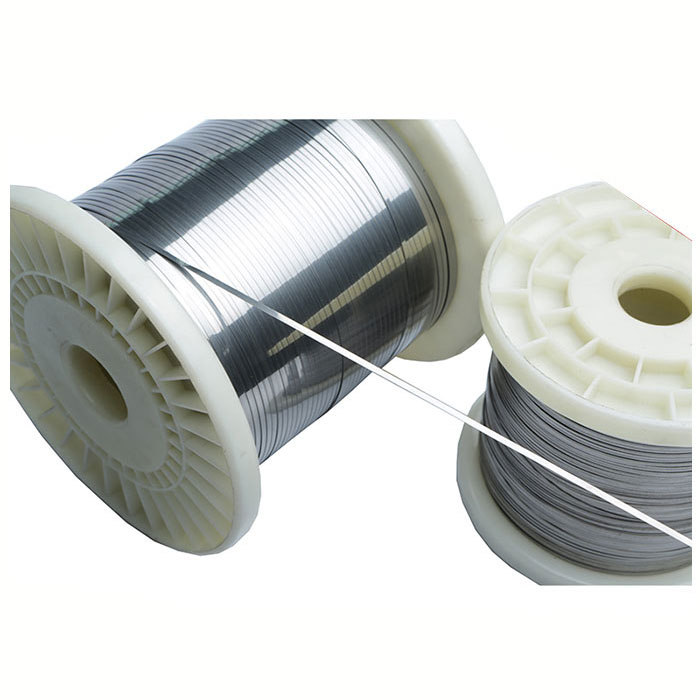

Packaging Details : Spool package with Carton box, Coil package with polybag

Material : Nickel, Chromium

Nickel(Min) : 30%

Resistivity : 1.04+/-0.05

Tensile Strength : 637MPA

Elongtation : ≥20%

Application : Heating, Resistivity

Condition : Hard / Soft

Sureface : Bright, Oxided, Acide

Name : resistance heating wire

Certification : CE,ROHS

Ni30Cr20 is an austenitic nickel-chromium alloy suitable for temperature applications up to 1100°C. This alloy is characterized by high resistivity, good oxidation resistance, good ductility after use and excellent weldability. Ni35Cr20 is used for a wide range of electric heating elements in domestic appliances.

Cr20Ni30 resistance wire is widely used in resistor adjusters to regulate the resistance value in a circuit, thereby controlling the magnitude of current or voltage. These adjusters are commonly found in various electronic devices and circuits, such as dimmers and speed controllers.

In certain circuits, it's necessary to limit the magnitude of current to protect other components from overload damage. Cr20Ni30 resistance wire is used as a key component in current limiters, generating appropriate resistance to restrict the flow of current.

Cr20Ni30 resistance wire can also be used to construct resistor networks for applications such as signal conditioning, filtering, and impedance matching in circuits. Resistor networks typically consist of multiple resistors, with Cr20Ni30 resistance wire providing the required resistance values.

In sensors and measurement equipment, Cr20Ni30 resistance wire is often used as a key component in resistance-based sensors for measuring physical quantities such as temperature, pressure, and humidity. Its stable resistance characteristics and high temperature resistance ensure the accuracy and reliability of the sensors.

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| μΩ·m,20℃ | |||||||

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| J/g.℃ | |||||||

| Thermal conductivity | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| KJ/m.h℃ | |||||||

| Coefficient of lines expansion | -- | 18 | 17 | 17 | 19 | 19 | |

| a×10-6/ | |||||||

| (20~1000℃) | |||||||

| Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | -- | Nonmagnetic | Nonmagnetic | Nonmagnetic | Weak magnetic | Weak magnetic | |

| ||

| ||

| ||

| ||

| ||

|

|

SWG18 Swg19 Nickel Chrome 30/20 Wire Ni30Cr20 Heating Wire Used For Resistors Images |