| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : DLX

Model Number : ErNiFe-6

Place of Origin : China Jiangsu

MOQ : 15

Payment Terms : L/C,T/T,Western Union,MoneyGram

Supply Ability : 500 tons per month

Delivery Time : 5-20 Days

Packaging Details : Spool package with Carton box, Coil package with polybag

Certification : CE,ROHS

Material : Ni. Cr. Fe. Mn. Ti

Elongation : ≥30%

Tensile strength Rm N/mm² : 560mpa

Grade : ASME SFA 5.14 ErNiFe-6

Melting point : 1320-1370℃

Certificate : ISO 9001

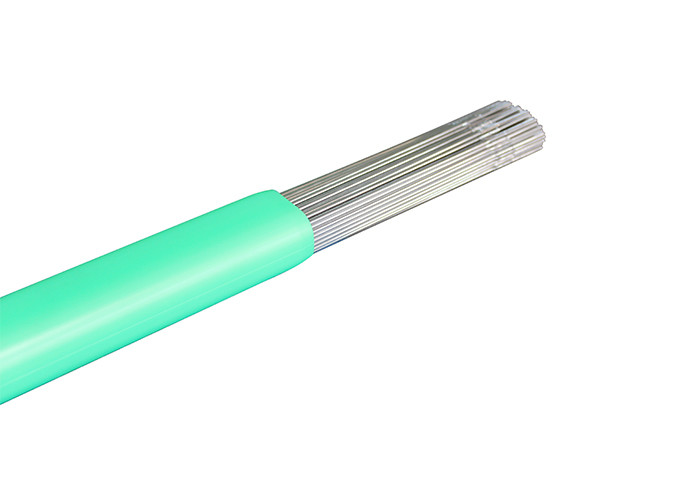

Price of AWS A5.14 3.2mm ErNiFe-6 incoloy alloy welding rod for sales

Nickel based welding wire ERNiCrFe-6 is used for shielded-metal-arc welding of INCOLOY alloys 800 and 800HT,INCONEL alloys 600 and 601, and nickel steels. ERNiCrFe-6 weld metal has excellent strength and oxidation resistance at high temperatures and retains impact resista nee at cryoge nic temperatures. Changzhou DLX alloy is one of the main producer in China for the ErNiCrFe-6 welding wire. ErNiCrFe properties are appropriate for the as-welded condition. Also ERNiCrFe-6 is the AWS designation for this material. N07092 is the UNS number.ErNiCrFe-6 also has a moderately low base cost among nickel-based welding fillers. In addition, it has a moderately low embodied energy and a moderately low melting temperature.The graph bars on the material properties cards below compare AWS ERNiCrFe-6 to: nickel-based welding fillers (top), all nickel alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relevant set. A half-full bar means it's 50% of the highest, and so on.

| Ni+Co | Cr | Fe | Cu | Ti | Mn | Si | S | P | C | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| 67 Min | 14-17 | 8 max | 0.5 max. | 2.5-3.5. | 2-2.7 | 0.35max | 0.015 max. | 0.03 Max | 0.08 max. | 0.5 Max |

| MIG | (15kg/spool) | Size |

|---|---|---|

| 0.8 1.2 2.4 3.2mm | ||

| TIG | (5kg/box),Strip |

ErNiCrFe-6 Filler Metal 92 is used for gas-tungsten-arc and gas-metal-arc welding of austenitic and ferritic steels and nickel alloys. Applications include joining INCONEL and INCOLOY alloys to stainless steels, carbon steels, and MONEL alloys; joining MONEL alloys and Nickel 200 to stainless steels; and joining stainless steels to carbon steels. The filler metal is also used for welding nickel steels. Filler Metal 92 provides high strength and corrosion resista nee at temperatures ranging from the cryogenic region to over 1800°F (980°C). Weld deposits can be age hardened for greater strength at temperatures to about 1300°F (700°C).

CHANGZHOU DLX ALLOY COMPANY was establish in 2016,our factory established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate.Our factory is becoming a high-tech company,We are professional in researching and producing special alloy material.The production process include melting,drawing,heat treatment,finishing and testing.We offer super alloy,welding wire,corrosion resistance alloy,precision alloy,FeCrAl alloy,NiCr alloy,CuNi alloy,in the form of wire,strip,ribbon,bar,tube,plate and etc.The administrative principle of our company is "intensifying inner supervision, complying with technical process and quality control, continuously adopting new technology to ensure the product quality". We employ some senior engineers to instruct technology, apply new technology and research new products. Our operation principle is "Quality first, Customer first". All the staff of our company would like to provide high quality and reasonably priced products for clients at home and abroad, and to make your products more competitive.

|

|

AWS A5.14 ErNiFe-6 Incoloy Alloy Welding Wire with 560mpa Tensile Strength and 1320-1370℃ Melting Point for High Temperature Resistance Images |